2021-03-17

原文链接:

https://www.sciencedirect.com/science/article/abs/pii/S0921344921001245

图片来源于网络(侵删)

文章亮点

(1)钢铁回收和木炭使用是低碳发展和循环生物经济的目标。

(2)巴西废钢库存规模不足以有效地回收利用。

(3)循环经济使巴西的炼钢碳排放量减少了65%。

(4)投资循环生物经济暂缓了更昂贵的低碳战略的执行。

2

文章导读

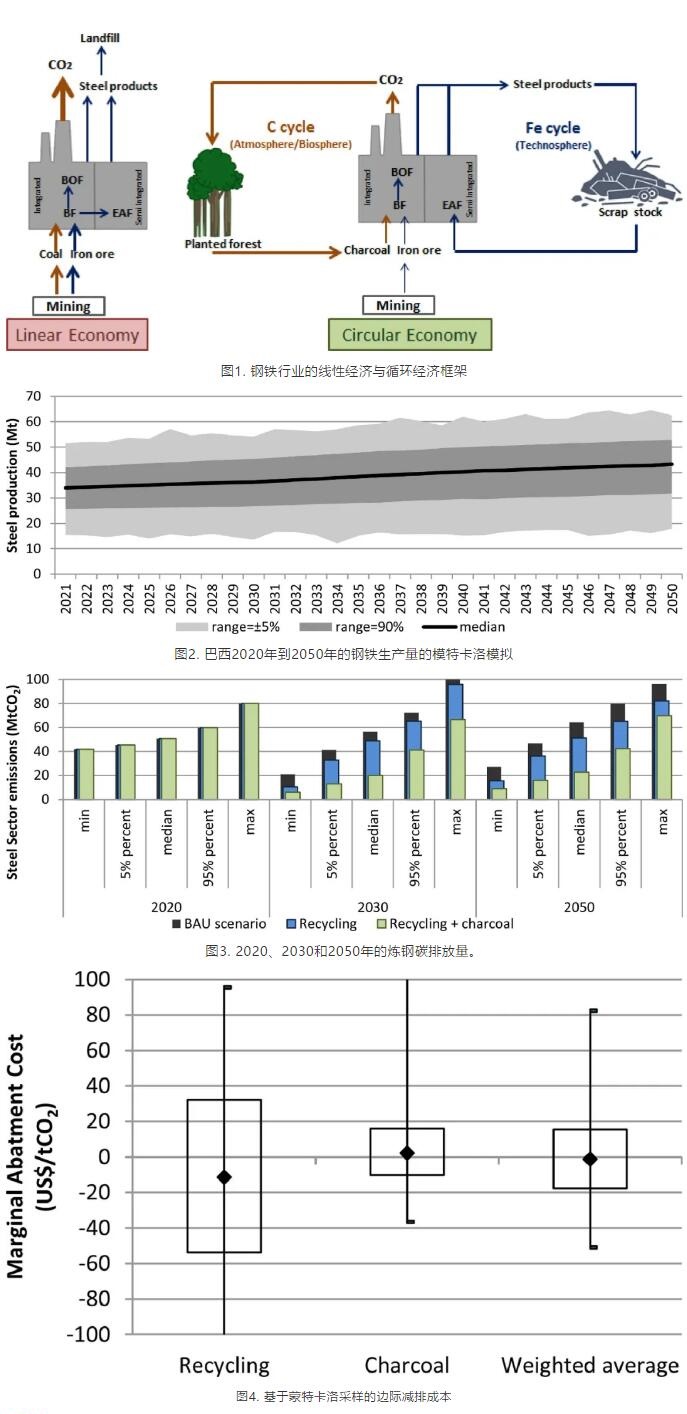

钢铁生产是全球变暖挑战的关键行业之一。为了满足国际能源署提出的可持续发展方案,该行业的二氧化碳强度需要每年降低1.9%,直到2030年。除缓解气候变化问题外,钢铁行业还具有循环经济的潜力。循环经济不仅仅限于减少二氧化碳,它还可以节省一次能源,并减少水和矿石的消耗以及废物的产生。在循环经济的基础上,循环生物经济旨在探索循环经济与生物质利用之间的重叠。基于此,本研究旨在基于循环生物经济对巴西钢铁行业碳减排潜力和成本进行分析。具体目标如下:(1)预测巴西到2050年的粗钢需求和产量; (2)估计巴西到2050年的废料和木炭供应量; (3)计算巴西在基准(BAU)情景和低碳情景下的碳排放量和生产成本。

3

原文摘要

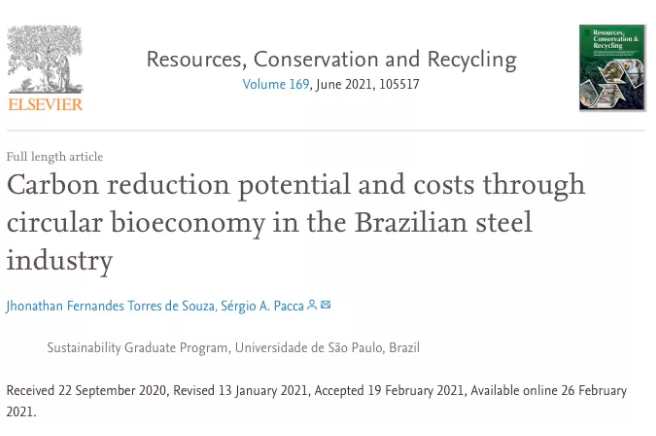

尽管钢铁回收属于循环经济战略,但巴西国内较小的废钢库存规模可能成为钢铁行业碳减排的瓶颈。在巴西,木炭生产可以作为减缓气候变化的替代品。本研究旨在评估巴西钢铁行业在低碳情景中的二氧化碳减排潜力和成本。基于此,本研究通过构建计量经济学模型预测了巴西到2050年的钢铁产量与碳排放。结果显示,钢铁回收的技术水平和木炭的经济可行性决定了低碳策略的效果。此外,本研究使用蒙特卡洛对预测产量进行了不确定性分析。结果显示,巴西2050年粗钢产量的碳排放中位数为64 Mt。钢铁生产的回收率达到36%,可以减少其中20%的碳排放。同时,86%的钢铁产量采用木炭作为燃料,可以减少其中65%的碳排放。此外,每吨碳排放平均节约1$的成本,但在45%的模拟情景中出现了成本为正值。与钢铁回收相比,木炭的减排成本更高,但不确定性更低。采用这些策略可以显着减少巴西炼钢的排放,暂缓其他更昂贵的替代方案的执行。然而,由于木炭的额外成本,政府需要制定经济政策和法规以确保可持续的木炭生产以及改善物流和废料市场的差异。

4

原文信息

Abstract

Although steel recycling is a credited circular economy strategy, domestic scrap stock may be a limitation to curb steelmaking carbon emissions. In Brazil, charcoal production can be a complementary climate change mitigation alternative to recycling. This study has assessed CO2 abatement potentials and costs in a low-carbon (LC) scenario for the Brazilian steel industry based on two circular bioeconomy-based options. For this purpose, Brazilian steel production was forecasted up to 2050 through an econometric model. The technical amount of scrap and the economic feasibility of charcoal have been estimated to determine the penetration of LC strategies. In addition, an uncertainty analysis was conducted using the Monte Carlo method. For the median value in the simulation, we found that crude steel production will emit 64 MtCO2 in 2050. A recycling share of 36% of the total steel production could reduce these emissions by 20%, and 86% of the remaining blast furnace production could be based on charcoal, improving the total abatement by 65%. The weighted average cost of the LC scenario is -$1/tCO2 for the median value in the simulation, but positive values have been found in 45% of the simulations. Charcoal presents higher abatement costs but less uncertainty than recycling. Such strategies can significantly reduce Brazilian steelmaking emissions, postponing other emerging or more expensive alternatives. Nevertheless, economic policies are needed due to additional costs of charcoal, in conjunction with law enforcement to ensure sustainable charcoal production, and regulations are needed to improve logistics and scrap market disparities.

本期编辑

帅晨阳,密西根大学环境与可持续性学院,博士研究生,研究方向:Data Science Application in Sustainability Sceince